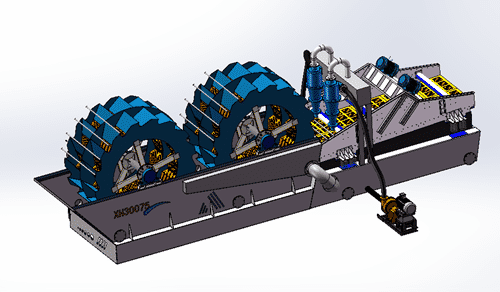

The double wheel sand washer is a new type of sand washing machine. On the basis of our original sand washing equipment, the equipment has been updated and upgraded to meet the needs of customers. The double wheel sand washing machine is skillful in docking two wheel bucket washing machines with fine sand recovery machines.

The whole machine has a reasonable structure and small area, which greatly reduces the investment cost for customers in the sand washing link. It integrates heavy water washing and fine sand dehydration and recycling.

1. Multiple functions, integrate sand washing, fines recycling, coarse and fines concentrated dehydration in one.

2. By connecting the two sand washers in series and the spray water pipes arranged around them, the material can be cleaner fully.

3. The fines recovery device can recover more than 90% of fines in the overflowing muddy water during sand washing, to make the finished sand grading well, and effectively improve the economic benefits.

4. If the muddy water treatment system is configured later, the pressure of concentrated filter press can be greatly reduced, so that the entire process can be optimized.

After the pre-processed material enters the first storage tank, the first washing wheel starts to rotate through the motor and reducer, and the material in the first storage tank is picked up from the water and passed through the mesh in the washing wheel. The water and the material below the mesh size are missing, and the qualified material is transferred to the second storage tank. During the rotation of the washing wheel, the material is in full contact with the water, and water is used to remove the impurities on the surface of the material. so the material is cleaner.

The second washing wheel repeats the process of the first washing wheel, and the material is cleaned again.

Then the material enters the dewatering device and removes a lot of moisture through the vibrating screen, which makes the material more convenient to store and transport.

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Hydrocyclone (mm) | Screen Panel (mm) | Power (kw) | Overall Size (mm) |

| 2DL40 | ≤10 | 20-40 | 1800*800 | 250*2 | 1200*2400 | 32.4 | 7120*3650*2160 |

| 2DL60 | ≤10 | 30-60 | 2500*1200 | 300*2 | 1500*3000 | 44 | 8900*5560*2750 |

| 2DL80 | ≤10 | 40-80 | 3000*1600 | 300*2 | 1800*4200 | 52 | 11600*5860*3370 |

| 2DL100 | ≤10 | 60-120 | 3000*1600 | 350*2 | 1800*4200 | 63 | 11600*5860*3370 |

| 2DL150 | ≤10 | 100-150 | 3600*2000 | 300*4 | 2400*4200 | 97 | 12800*6560*3970 |

| 2DL200 | ≤10 | 120-200 | 3600*2400 | 350*4 | 3000*4800 | 126 | 12800*7150*4170 |

| 2DL250 | ≤10 | 160-250 | 4200*3000 | 300*6 | 3600*6000 | 164 | 14400*7740*4860 |

All product information including pictures, types, data, performance, specifications on this website is for your reference only. Adjustment of above-mentioned contents may take place. You can refer to the real products and product manuals for some specific messages. Except the special explanation, data interpretation right involved in this website is owned by LZZG.

Inquiry