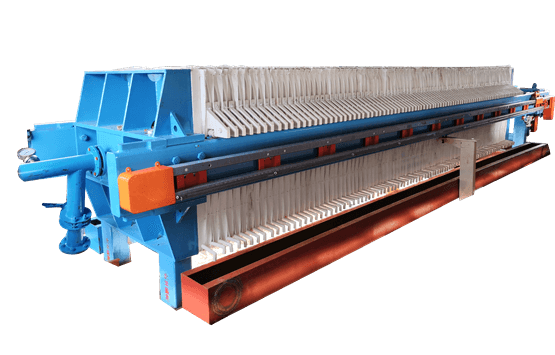

Our filter presses are supplied for a wide application in municipal & industrial wastewater treatment. Feed mud concentration always be 30%-40%, then mud will become mud cake and the humidity is around 20% after processed. LZZG filter press is a kind of Plate and Frame Filter Press, some now call it as “Chamber Filter Press”. Typically, no flocculant are needed to help dewatering on a plate filter press.

1. The structure is simple, the operation is easy and stable, and the maintenance is convenient.

2. Less wearing parts and low maintenance costs.

3. The filter area has a flexible sele

4. Compared with other types of dewatering machines, the mud cake has high solid content, small floor space, and convenient transportation and other post-treatment.

Slurry is pumped into the filter press by high-pressure slurry pumps, the mixture flows through the filter medium (filter cloth), the solids stay on the filter cloths, forming filter cake; the filtrate exits the filter plates through the corner ports into the manifold, If it is not wanted the filtrate can be drained away for safe disposal.

| Model | Capacity (t/h) | Filter Area (m²) | Filter Plate (mm) | Plate Number (block) | Filter Pressure (mpa) | Overall Size (mm) |

| G100-100 | 2-3 | 100 | 1000*1000*60 | 62 | 0.6-0.8 | 7050*1625*1280 |

| G250-125 | 5-7 | 250 | 1250*1250*70 | 95 | 0.6-0.8 | 10630*2540*1640 |

| G500-150 | 11-12 | 500 | 1500*1500*78 | 128 | 0.6-0.8 | 14550*2820*1890 |

| G800-200 | 18-20 | 800 | 2000*2000*83 | 114 | 0.6-0.8 | 14700*3500*2390 |

All product information including pictures, types, data, performance, specifications on this website is for your reference only. Adjustment of above-mentioned contents may take place. You can refer to the real products and product manuals for some specific messages. Except the special explanation, data interpretation right involved in this website is owned by LZZG.

Inquiry