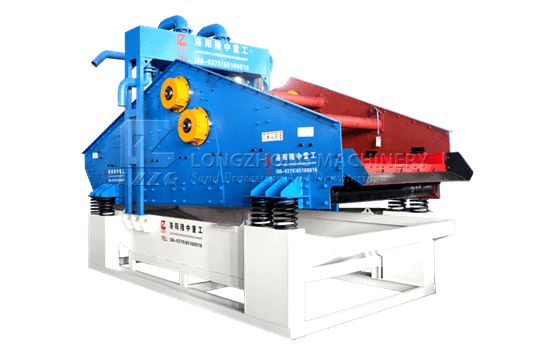

Fine sand recovery machine is a combination of dewatering screen and hydrocyclone that is specifically developed integrates dewatering, screening and fine material recovery on the basis of the original recycling machine, and achieves the effect of multi-purpose machine. Fines recovery unit is generally directly used at the rear of sand washer, dewatering screen further dehydrates the finished material of sand washing machine, and recovery system effectively extracts and recovers the fines in tail water overflowed by sand washing machine to realize the coarse and fine sand centralized dehydration and recovery.

1. Both dehydration and recovery functions, which solves the problem of high fineness modulus and low stone powder content of finished sand in artificial aggregate processing system.

2. Above 95% fines recovery rate brought the direct economic benefit to customers is more than 15%, which has both environmental protection and economic benefits.

3. Improve the quality and productivity of finished products, fully solve the problems of sand washing machine.

4. Secondary washing function make the products cleaner.

5. Fines recovery unit can also provide more flexible process configuration for customer to meet the different production requirements besides the existing fixed group form.

6. Multi-function, easy to operate, saving investment cost and floor space.

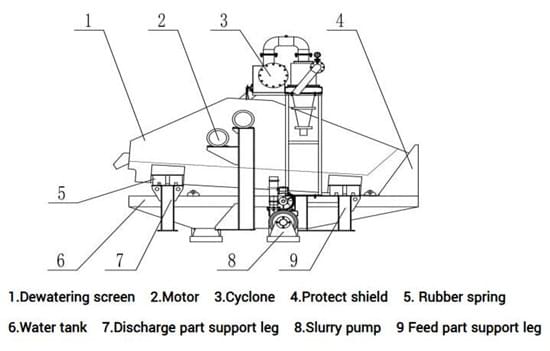

About No.6 sand recycling system, we still choose polyurethane screen as its main screening part, and add recycling part on TS dewatering screen.

Sand after sand washer is fed onto polyurethane screen for dewatering, waste sand water through steel chute or rubber pipe in water tank and extracted by slurry pump into high pressure sediment separator, fine sand 0.16-3mm is sprayed onto polyurethane screen also for de-watering, the waste water is back to return box and flowing out.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| LZ1224D-55 | ≤10 | 20-40 | 1200X2400 | 250X2 | 26.4 | 2760X4850X2780 |

| LZ1530D-65 | ≤10 | 30-60 | 1500X3000 | 300X2 | 36 | 3300X5250X3000 |

| LZ1842D-75 | ≤10 | 40-80 | 1800X4200 | 350X2 | 48 | 4600X5560X3520 |

| LZ1842J-75 | ≤10 | 60-100 | 1800X4200 | 350X2 | 52 | 4600X5560X3520 |

| LZ2442J-120 | ≤10 | 100-150 | 2400X4200 | 300X4 | 82 | 4600X6250X3600 |

| LZ3048J-140 | ≤10 | 120-200 | 3000X4800 | 350X4 | 104 | 5400X7000X4200 |

| LZ3660J-180 | ≤10 | 150-250 | 3600X6000 | 300X6 | 134 | 6600X7000X4800 |

All product information including pictures, types, data, performance, specifications on this website is for your reference only. Adjustment of above-mentioned contents may take place. You can refer to the real products and product manuals for some specific messages. Except the special explanation, data interpretation right involved in this website is owned by LZZG.

Inquiry