Base on years’ experience and technology, LSX spiral sand washing machine is designed to provide bigger capacity and higher cleaning level than traditional one. It is also called “stone washing machine” as its input material size is at most 30mm. Now it is widely used for cleaning materials in quarry, minerals, building materials, transportation, chemical industry, water conservancy and hydropower, cement mixture station and so on.

1. Reasonable structure, convenient maintenance, small power consumption. The novel sealing structure of the spiral stone washer, the whole sealing oil bath type transmission device and the adjustable overflow weir plate ensure that the series of products are durable, with good cleaning and dewatering effects, and the fine products are not disorderly.

2. Large processing capacity, because the screw sand washing machine sand washing principle is not to use a bucket to “catch”, so its processing capacity has been greatly improved.

3. The higher energy utilization rate reduces the energy loss caused by the wheel bucket in the process of lifting, so that the energy can be better utilized.

4. High cleanliness. More time and times for the sand to be cleaned compared to wheel type sand washer.

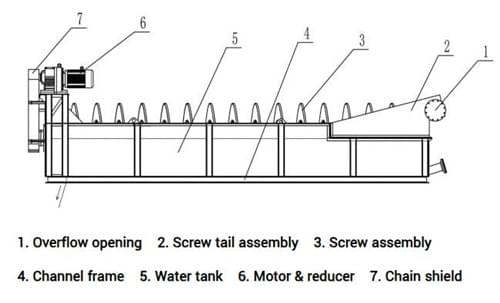

Screw sand washer is based on the principle of different specific gravity of solid particles and the different sedimentation rate in liquid to realize washing process. And is equipped with water spray pipes in cleaning tank. When working, a certain amount of water is supplied to flush and submerge the raw sand in cleaning tank from the inlet.

At the same time, the spiral is continuously stirred and graded, and dirt impurities, mud and tiny solid particles are suspended in the upper turbid water, gradually overflowing from the low-end overflow weir; the coarser sand particles sink to the bottom of the tank by gravity. As the spiral rotates continuously, the coarse sand is continuously agitated and graded in the water, so that the sand is fully washed.

| Model | Feeding Size (mm) | Capacity (t/h) | Spiral Diameter (mm) | Spiral Shaft | Tank Length (mm) | Power (kw) | Overall Size (mm) |

| LX0760 | ≤10 | 20-40 | 760 | 1 | 6000 | 7.5 | 5700*1420*1900 |

| LX0920 | ≤10 | 30-60 | 920 | 1 | 8000 | 11 | 8710*1630*2080 |

| LX1120 | ≤10 | 40-80 | 1120 | 1 | 8000 | 18.5 | 9230*1840*2130 |

| LX1500 | ≤10 | 50-100 | 1500 | 1 | 8000 | 22 | 9620*2230*2480 |

| 2LX0920 | ≤10 | 60-120 | 920*2 | 2 | 8000 | 11*2 | 8710*2600*2080 |

| 2LX1120 | ≤10 | 80-160 | 1120*2 | 2 | 8000 | 18.5*2 | 9230*3050*2130 |

| 2LX1500 | ≤10 | 120-250 | 1500*2 | 2 | 8000 | 22*2 | 9620*3730*2480 |

All product information including pictures, types, data, performance, specifications on this website is for your reference only. Adjustment of above-mentioned contents may take place. You can refer to the real products and product manuals for some specific messages. Except the special explanation, data interpretation right involved in this website is owned by LZZG.

Inquiry