This Y series vibrating screen is vibrated by the circling motion. It is high efficient screen for filter materials into multiple grade according to the gravel size. For the compact structure and the convenient installation, it is the ideal screening device for prefilter of the feed materials before the primary crushing in the quarry site, it also can be used as separation and filtration solely. The vibrating screen adopts cylinder type eccentric shaft vibrator and partial block to adjust the amplitude. The materiel sieve drip line is long and more sieving specifications. The circular vibrating screen can also be used for production classifying in quarry, mine, construction, electricity, chemical industry,etc.

1. Vibrating screen YA is of several decks whose moving track is round.

2. The moving track of material is very long; the size of material can be separated into several specifications.

3. It adopts cylinder style inspiring vibrator device and eccentric shaft to adjust. It has the features of reliable structure, strong vibrating generation, high screening efficient, low noise, easy maintenance, safe performance, etc.

4. It is widely used in separating gravel and is also suitable for mining, construction material, transportation, energy, chemical industry and so on.

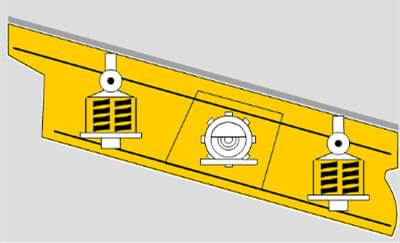

Y series vibrating screen is mainly composed of screen box, screen mesh, vibrator, damping spring device, bottom frame and so on. The side plate of vibrating screen is made of high quality steel plate.It is connected with the beam and bottom seat of the vibration exciter with high strength bolts or ring slot rivets, and cylinder type eccentric shaft exciter and eccentric block are used to adjust the amplitude.

Vibrator is installed on the screen box side plate to drive vibrator eccentric block produce high-speed rotation through v-belt by the motor so that could produce large centrifugal force to stimulate the screen box produce a certain amplitude of circular movement.The material on the screen is subjected to the impulse passed by the screen box on the titled screen surface and produces continuous throwing motion.So particles that are smaller than the screen hole pass through the screen so as to achieve classification when material enters the screen surface.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Screen Area (m²) | Power (kw) | Overall Size (mm) |

| 2YK1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 11 | 5000*2900*2900 |

| 2YK1860 | 0-200 | 0-200 | 1800*6000 | 10.8 | 15 | 6200*3400*3500 |

| 3YK1860 | 0-300 | 0-200 | 1800*6000 | 10.8 | 22 | 6200*3400*4100 |

| 2YK2160 | 0-200 | 0-250 | 2100*6000 | 12.6 | 22 | 6200*3700*3500 |

| 3YK2160 | 0-300 | 0-250 | 2100*6000 | 12.6 | 22 | 6200*3700*4100 |

| 2YK2460 | 0-200 | 0-300 | 2400*6000 | 14.4 | 22*2 | 6200*4100*3800 |

| 3YK2460 | 0-300 | 0-300 | 2400*6000 | 14.4 | 30*2 | 6200*4100*4400 |

| 2YK2472 | 0-200 | 0-300 | 2400*7200 | 16.8 | 22*2 | 7400*4000*4000 |

| 3YK2472 | 0-300 | 0-300 | 2400*7200 | 16.8 | 30*2 | 7400*4100*4600 |

| 2YK3072 | 0-200 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4100 |

| 3YK3072 | 0-300 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4700 |

| 3YK3672 | 0-300 | 0-350 | 3600*7200 | 25.92 | 37*2 | 7400*5400*4700 |

All product information including pictures, types, data, performance, specifications on this website is for your reference only. Adjustment of above-mentioned contents may take place. You can refer to the real products and product manuals for some specific messages. Except the special explanation, data interpretation right involved in this website is owned by LZZG.

Inquiry